Available for licensed manufacturing. Patent Pending.

Overview of existing marketplace:

Most piston/manifold based machines are use pneumatic pressure to expand or contract the piston, thereby moving the adjoining armature. The pneumatic material can be petroleum base fluids, water or air. The basic principle is the same, an external pump creates high pressure using manual or powered means to push the fluid into or release the fluid out of the piston and manifold system. This is a very well known approach and is used in large and small machinery. It has many drawbacks. It does not scale to very small systems well. It also requires numerous parts that must work together. Failures within the pump, tubes that carry the high pressure fluid, and leaks within the seals of the pistons can cause poor performance or complete failure to the system. Also the high pressure required can pose a danger to those using or maintaining pneumatic pistons/manifold systems.

Our invention reduces the number of parts needed, simplifies the system, and can scale to very small sizes. Even to sizes impossible to build pneumatic piston systems at. Also it is far safer than pneumatic pistons, and has environmental benefits of not needing to use petroleum base fluids, that must be refilled and deposed of.

Brief Summary:

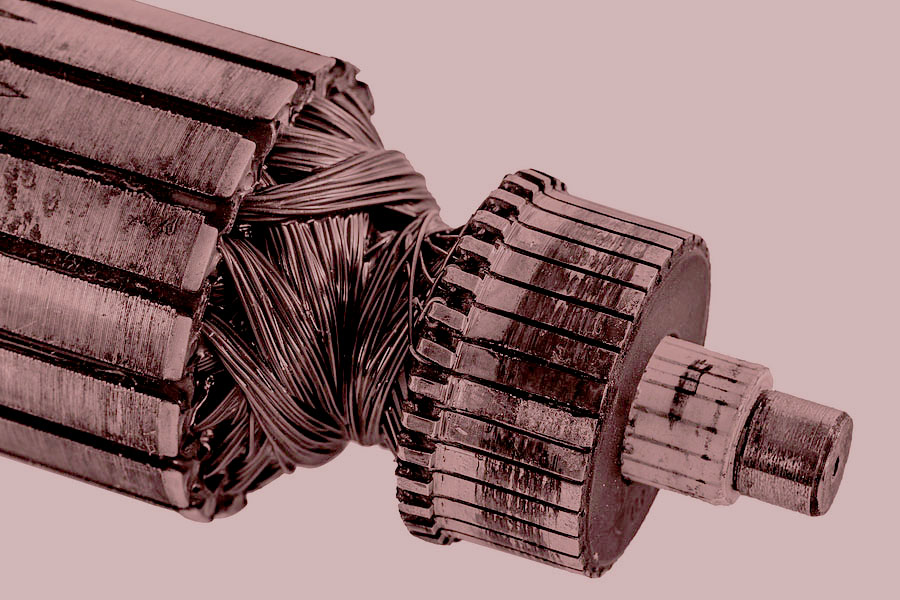

Piston like machine functions utilizing a printed coil magnet technology. The structure is similar to pistons and piston/manifold designs, but require less parts. This can be accomplished in various designs, the first is a simple example; 2 tubes with different diameters. One tube can slide inside of the other tube. Both tubes contain or are themselves printed coil magnets. Both tubes have a series of independently controlled printed coil magnets. When the tubes are together, some of the magnets in the inner tube will be charged to produce a positive field. Others coils in the outer tube will be charged to produce a negative field. This approach can be used to expand or contract the “piston”. More magnets energized will produce a stronger force. Based upon the size of each magnet, voltage used or other dampening controls can provide accurate control of the piston. Numerous rods/tubes in series, or groups can be used to provide greater strength or surface pressure. Pistons can also arranged in a manifold to add combined pressure of a series of pistons against a surface.

For more detail, and if your firm is interested in licensing this Patent Pending invention.